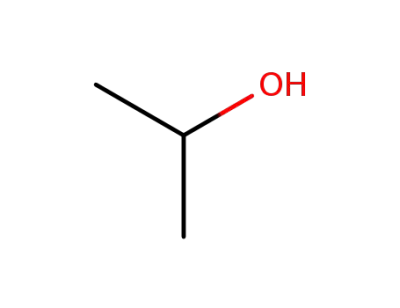

67-63-0

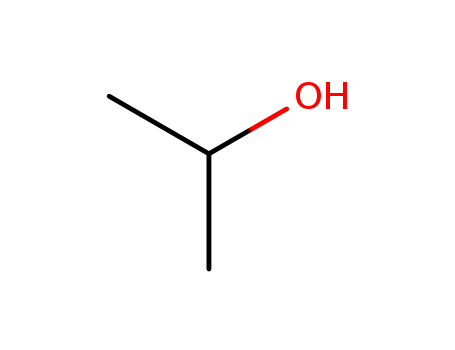

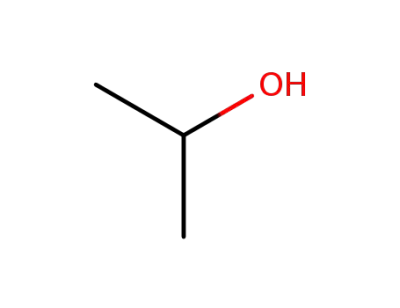

- Product Name:Isopropanol

- Molecular Formula:C3H8O

- Purity:99%

- Molecular Weight:60.0959

Product Details

High quality purity >99% Isopropanol 67-63-0 for sale

- Molecular Formula:C3H8O

- Molecular Weight:60.0959

- Appearance/Colour:colourless liquid

- Vapor Pressure:33 mm Hg ( 20 °C)

- Melting Point:-89.5 °C

- Refractive Index:n20/D 1.377(lit.)

- Boiling Point:72.993 °C at 760 mmHg

- PKA:17.1(at 25℃)

- Flash Point:11.667 °C

- PSA:20.23000

- Density:0.791 g/cm3

- LogP:0.38710

Isopropanol(Cas 67-63-0) Usage

|

Chemical Description |

Isopropanol, also known as rubbing alcohol, is a colorless, flammable liquid used as a solvent and disinfectant. |

|

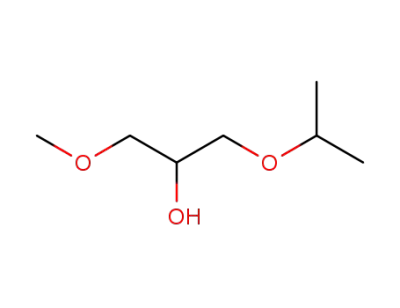

description |

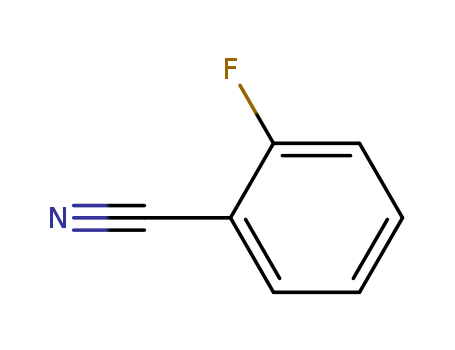

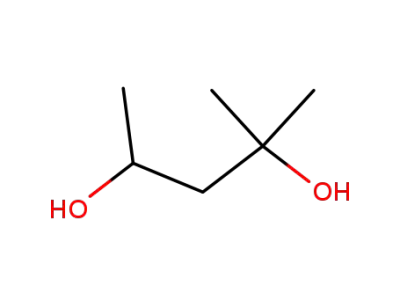

Isopropanol is also known as isopropyl alcohol. It is the simplest secondary alcohol and is one of the isomers of n-propanol. It is a kind of flammable liquid which is colorless with strong smell being similar to the smell of the mixture of ethanol and acetone. It is soluble in water, alcohol, ether, benzene, chloroform and most organic solvents and is miscible with water, alcohol, ether and can form azeotrope with water. Density (specific gravity): 0.7863g/cm3, melting point:-88.5 ℃, boiling point: 82.5 ℃, flash point: 11.7 ℃, ignition point: 460 ℃, refractive index: 1.3772. Its vapor can cause slight irritation on the eyes, nose and throat; it can be absorbed through the skin. Its vapor can form explosive mixture with air. Its explosion limit is 2.0% to 12% (by volume). It belongs to a moderate explosive hazardous material and flammable, low toxic substance. The toxicity of its vapors is twice as high as ethanol while oral administration causes the opposite toxicity. Figure 1 is the structural formula of isopropanol. In many cases, isopropanol can substitute ethanol as the solvent and is a good solvent and chemical raw materials which can be applied to not only painting, pharmaceuticals, pesticides, cosmetics and other industries, but also the production of acetone, isopropyl ester, isopropylamine (the raw material for production of atrazine), di-isopropyl ether, isopropyl acetate and thymol crystal etc. It was the first product which is made from the petroleum raw material in the history of the development of petrochemicals. |

|

Production Process |

In 1855, Frenchman M. Berthelot first reported the production of isopropanol through the hydration reaction between propylene and sulfuric acid, called indirect hydration. In 1919, the Americans C. Ellis had conducted industrial development on this. At the end of 1920, the American Standard Oil Company of New Jersey adopted the approach of Ellis Act and established the production equipment for putting into formal production. In 1951, the British company Imperial Chemical Industries began to produce isopropanol with the direct hydration method from propylene. Since then, many countries have used this method and made related improvements. Indirect hydration reaction: propylene is first reacted with sulfuric acid to obtain isopropyl hydrogen sulfate, which generates isopropanol after hydrolysis, and the reaction of the formula: CH3CH = CH2 + H2SO4 → (CH3) 2CHOSO3H (CH3) 2CHOSO3H + H2O─ → (CH3) 2CHOH + H2SO4 the concentration of the applied sulfuric acid is generally greater than 60% (by mass), and the reaction is conducted at 2~2.8MPa and 60~65 ° C; The hydrolysis reaction happens at slight increased pressure and at below 30 ° C. Direct hydration: propylene directly has hydration reaction with water in the presence of a catalyst upon heating and increased pressure to generate isopropanol with a selectivity of 96%. Reaction is: CH3CH = CH2 + H2O → (CH3) 2CHOH; the used catalyst includes tungsten compound, phosphate and ion exchange resin; the commonly used catalyst is phosphoric acid catalyst with carrier (see solid acid catalyst) with conditions of 2~6MPa, 240~260 ° C. Compared with the indirect method, this method does not have issue regarding to sulfuric acid corrosion and dilute acid concentration and therefore, it dominant in industrial production. The above information is edited by the lookchem of Dai Xiongfeng. |

|

Toxicity |

ADI value is not specified (FAO/WHO, 2001). LD5050: 45rag/kg (rat, oral). |

|

Limited use |

FEMA (mg/kg): soft drinks: 25; sweets: 10 to 75; baked good: 75. |

|

Preparation |

Isopropyl alcohol may be prepared from propylene; by the catalytic reduction of acetone, or by fermentation of certain carbohydrates. |

|

Definition |

ChEBI: Isopropyl Alcohol is a secondary alcohol that is propane in which one of the hydrogens attached to the central carbon is substituted by a hydroxy group. It is an isomer of propyl alcohol with antibacterial properties. |

|

Application |

Isopropyl Alcohol is used in a variety of applications including as a solvent for industrial processes and coating; as a component in cleaning, car care and deicing products; as a wetting agent for printing inks and as a feedstock in the manufacture of ester and Mogas/Luboil additives.isopropyl alcohol is a carrier, anti-bacterial, and solvent for skin care lotions. Isopropyl alcohol is made from propylene, a petroleum derivative.When compared to ethanol, 50% less is required for nucleic acid precipitation, thus minimizing the total volume to be centrifuged for DNA or RNA recovery.Isopropyl alcohol 70% is used as an ingredient in alcohol swabs and alcohol wipes for wound cleaning, it is found in hand sanitizers, and in ear drops to prevent swimmer's ear. |

|

Aroma threshold values |

Detection: 40 to 601 ppm |

|

General Description |

Volatile, colorless liquid with a sharp musty odor like rubbing alcohol. Flash point of 53°F. Vapors are heavier than air and mildly irritating to the eyes, nose, and throat. Density approximately 6.5 lb / gal. Used in making cosmetics, skin and hair preparations, pharmaceuticals, perfumes, lacquer formulations, dye solutions, antifreezes, soaps, window cleaners. Sold in 70% aqueous solution as rubbing alcohol. |

|

Air & Water Reactions |

Highly flammable. Water soluble. |

|

Reactivity Profile |

Isopropyl Alcohol can react with AIR and OXYGEN over time to form unstable peroxides that can explode. Contact with 2-butanone increases the rate of peroxide formation. An explosive reaction occurs when Isopropanol is heated with (aluminum isopropoxide + crotonaldehyde). Forms explosive mixtures with trinitromethane and hydrogen peroxide. Reacts with barium perchlorate to form a highly explosive compound. Ignites on contact with dioxygenyl tetrafluoroborate, chromium trioxide and potassium-tert-butoxide. Vigorous reactions occur with (hydrogen + palladium), nitroform, oleum, COCl2, aluminum triisopropoxide and oxidizing agents. Reacts explosively with phosgene in the presence of iron salts. Incompatible with acids, acid anhydrides, halogens and aluminum . Isopropanol can react with PCl3, forming toxic HCl gas. (Logsdon, John E., Richard A. Loke., sopropyl Alcohol. Kirk-Othmer Encyclopedia of Chemical Technology. John Wiley & Sons, Inc. 1996.). |

|

Health Hazard |

Exposures to isopropyl alcohol cause irritation to the eyes and mucous membranes. Exposures to isopropyl alcohol for 3–5 min (400 ppm) caused mild irritation of the eyes, nose, and throat, and at 800 ppm these symptoms became severe. Ingestion or an oral dose of 25 mL in 100 mL of water produced hypotension, facial flushing, bradycardia, and dizziness. Ingestion in large quantities caused extensive hemorrhagic tracheobronchitis, bronchopneumonia, and hemorrhagic pulmonary edema. Prolonged skin contact with isopropyl alcohol caused eczema and sensitivity. Delayed dermal absorption is attributed to a number of pediatric poisonings that have occurred following repeated or prolonged sponge bathing with isopropyl alcohol to reduce fever. In several cases, symptoms included respiratory distress, stupor, and coma. Laboratory animals exposed to isopropyl alcohol develop poisoning with symptoms of hind leg paralysis, unsteadiness, lack of muscular coordination, respiratory depression, and stupor. Isopropyl alcohol is a potent CNS depressant, and in large doses causes cardiovascular depression. |

|

Fire Hazard |

Isopropyl Alcohol(IPA) is highly flammable in its liquid and vapor forms and flammable atmospheres can be created at temperatures as low as 540°F /120℃ . This means that any environment where IPA is being used needs to be well ventilated. It should be kept away from heat and open flame. As the vapour is heavier than air, it may spread along the ground, so care needs to be taken that the vapour is not ignited by a distant source. |

|

Pharmaceutical Applications |

Isopropyl alcohol (propan-2-ol) is used in cosmetics and pharmaceutical formulations, primarily as a solvent in topical formulations.( It is not recommended for oral use owing to its toxicity. Although it is used in lotions, the marked degreasing properties of isopropyl alcohol may limit its usefulness in preparations used repeatedly. Isopropyl alcohol is also used as a solvent both for tablet film-coating and for tablet granulation, where the isopropyl alcohol is subsequently removed by evaporation. It has also been shown to significantly increase the skin permeability of nimesulide from carbomer 934. Isopropyl alcohol has some antimicrobial activity and a 70% v/v aqueous solution is used as a topical disinfectant. Therapeutically, isopropyl alcohol has been investigated for the treatment of postoperative nausea or vomiting. |

|

Safety |

Isopropyl alcohol is about twice as toxic as ethanol and should therefore not be administered orally; isopropyl alcohol also has an unpleasant taste. Symptoms of isopropyl alcohol toxicity are similar to those for ethanol except that isopropyl alcohol has no initial euphoric action, and gastritis and vomiting are more prominent; see Alcohol. Delta osmolality may be useful as rapid screen test to identify patients at risk of complications from ingestion of isopropyl alcohol. The lethal oral dose is estimated to be about 120–250mL although toxic symptoms may be produced by 20 mL.Adverse effects following parenteral administration of up to 20mL of isopropyl alcohol diluted with water have included only a sensation of heat and a slight lowering of blood pressure. However, isopropyl alcohol is not commonly used in parenteral products.Although inhalation can cause irritation and coma, the inhalation of isopropyl alcohol has been investigated in therapeutic applications.Isopropyl alcohol is most frequently used in topical pharmaceutical formulations where it may act as a local irritant. When applied to the eye it can cause corneal burns and eye damage.LD50 (dog, oral): 4.80 g/kgLD50 (mouse, oral): 3.6 g/kgLD50 (mouse, IP): 4.48 g/kgLD50 (mouse, IV): 1.51 g/kgLD50 (rabbit, oral): 6.41 g/kgLD50 (rabbit, skin): 12.8 g/kgLD50 (rat, IP): 2.74 g/kgLD50 (rat, IV): 1.09 g/kgLD50 (rat, oral): 5.05 g/kg |

|

Synthesis |

Synthetically prepared from acetylene or propylene. |

|

Carcinogenicity |

CD-1 mice were exposed by inhalation to 0, 500, 2500, or 5000 ppm of isopropanol vapor for 6 h/day, 5 days/week for 18 months. An additional group of mice (all exposure levels) were assigned to a recovery group that were exposed to isopropanol for 12 months and then retained until study termination at 18 months. There was no increased frequency of neoplastic lesions in any of the isopropanol-exposed animals. Nonneoplastic lesions were limited to the testes (males) and the kidney. In the testes, enlargement of the seminal vesicles occurred in the absence of associated inflammatory or degenerative changes. The kidney effects included tubular proteinosis and/or tubular dilatation. The incidence of testicular and kidney effects was not increased in the isopropanol-exposed recovery animals. |

|

Environmental Fate |

The vast majority of isopropanol in the environment originates from manufacturing processes. Small amounts are produced by certain microbes, fungi, and yeast. The high volatility of isopropanol ensures that when it is released into the environment in any state, it eventually ends up in the atmosphere. There, it can be degraded by hydroxyl radicals or it can return to soil or water through precipitation. Its half-life in the environment is approximately 3.2 days and is highly biodegradable; bioaccumulation in plants and animals does not occur. |

|

storage |

Isopropyl alcohol should be stored in a cool, dry, well-ventilated area in tightly sealed containers with a proper label. Outside or detached storage is preferable. Inside storage should be a flammable liquids storage room or cabinet. Workers should not store isopropyl alcohol above 37°C (100°F). Containers of isopropyl alcohol should be protected from physical damage and contact with air, and should be stored separately from strong oxidizers, acetaldehyde, chlorine, ethylene oxide, acids, and isocyanates. Isopropyl alcohol should be transported to the nearest laboratory as quickly as possible in cool containers. |

|

Purification Methods |

Isopropyl alcohol is prepared commercially by dissolution of propene in H2SO4, followed by hydrolysis of the sulfate ester. Major impurities are water, lower alcohols and oxidation products such as aldehydes and ketones. Purification of isopropanol follows substantially the same procedure as for n-propyl alcohol. Isopropanol forms a constant-boiling mixture, b 80.3o, with water. Most of the water can be removed from this 91% isopropanol by refluxing with CaO (200g/L) for several hours, then distilling. The distillate can be dried further with CaH2, magnesium ribbon, BaO, CaSO4, calcium, anhydrous CuSO4 or Linde type 5A molecular sieves. Distillation from sulfanilic acid removes ammonia and other basic impurities. Peroxides [indicated by liberation of iodine from weakly acid (HCl) solutions of 2% KI] can be removed by refluxing with solid stannous chloride or with NaBH4 then the alcohol is fractionally distilled. To obtain isopropanol containing only 0.002M of water, sodium (8g/L) is dissolved in material dried by distillation from CaSO4. Isopropyl benzoate (35mL) is then added and, after refluxing for 3hours, the alcohol is distilled through a 50-cm Vigreux column (p 11). [Hine & Tanabe J Am Chem Soc 80 3002 1958.] Other purification steps for isopropanol include refluxing with solid aluminium isopropoxide, refluxing with NaBH4 for 24hours, and removing acetone by treatment with, and distillation from, 2,4-dinitrophenylhydrazine. Peroxides re-form in isopropanol if it is kept for several days in contact with air. [Beilstein 1 IV 1461.] |

|

Toxicity evaluation |

Isopropanol is similar to other alcohols in its ability to induce central nervous system (CNS) depression by enhancing inhibitory neuronal activity and antagonizing excitatory neuronal activity. It also can cause localized irritation upon contact with skin and mucous membranes after dermal exposure and ingestion, respectively. |

|

Incompatibilities |

Incompatible with oxidizing agents such as hydrogen peroxide and nitric acid, which cause decomposition. Isopropyl alcohol may be salted out from aqueous mixtures by the addition of sodium chloride, sodium sulfate, and other salts, or by the addition of sodium hydroxide. |

|

Precautions |

Workers should wash hands and face thoroughly after handling isopropyl alcohol. Workers should wear gloves, safety glasses and a face shield, boots, apron, and a full impermeable suit is recommended if exposure is possible to a large portion of the body. |

|

Regulatory Status |

Included in the FDA Inactive Ingredients Database (oral capsules, tablets, and topical preparations). Included in nonparenteral medicines licensed in the UK. Included in the Canadian List of Acceptable Non-medicinal Ingredients. |

InChI:InChI=1/C3H8O/c1-2-3-4/h4H,2-3H2,1H3

67-63-0 Relevant articles

HOMOGENEOUS HYDROGENATION OF KETONES TO ALCOHOLS WITH RUTHENIUM COMPLEX CATALYSTS

Sanchez-Delgado, R.A.,Ochoa, O.L. De

, p. 427 - 434 (1980)

A number of ruthenium triphenylphosphine...

Improved (photo)catalytic propene hydration in a gas/solid system by using heteropolyacid/oxide composites: Electron paramagnetic resonance, acidity, and role of water

García-López, Elisa I.,Marcì, Giuseppe,Pomilla, Francesca R.,Liotta, Leonarda F.,Megna, Bartolomeo,Paganini, Maria C.,Gionco, Chiara,Giamello, Elio,Palmisano, Leonardo

, p. 1900 - 1907 (2017)

Binary materials composed of the oxides ...

Nucleophilic substitution in radicals derived from isopropyl chloride

Kosobutskii

, p. 1050 - 1052 (2003)

-

Rh-CeO2 Interaction induced by High-temperature Reduction. Characterization and Catalytic Behaviour in Transient and Continuous Conditions

Trovarelli, Alessandro,Dolcetti, Giuliano,Leitenburg, Carla de,Kaspar, Jan,Finetti, Paola,Santoni, Antonino

, p. 1311 - 1320 (1992)

The effects of the high-temperature redu...

Kinetics of an Associative Ligand-Exchange Process: Alcohol Exchange with Arsenate(V) Triesters

Baer, Carl D.,Edwards, John O.,Kaus, Malcolm J.,Richmond, Thomas G.,Rieger, Philip H.

, p. 5793 - 5798 (1980)

The rate of alcohol exchange with trialk...

The heme monooxygenase cytochrome P450cam can be engineered to oxidize ethane to ethanol

Xu, Feng,Bell, Stephen G.,Lednik, Jaka,Insley, Andrew,Rao, Zihe,Wong, Luet-Lok

, p. 4029 - 4032 (2005)

(Graph Presented) A NADH turnover rate o...

Hydrodeoxygenation of glycerol into propanols over a Ni/WO3–TiO2 catalyst

Greish, Alexander A.,Finashina, Elena D.,Tkachenko, Olga P.,Nikul'shin, Pavel A.,Ershov, Mikhail A.,Kustov, Leonid M.

, p. 119 - 120 (2020)

Hydrodeoxygenation of glycerol in a flow...

TiO2/polymeric supported silver nanoparticles applied as superior nanocatalyst in reduction reactions

Sedghi, Roya,Asadi, Shima,Heidari, Bahareh,Heravi, Majid M.

, p. 65 - 73 (2017)

A novel polymeric nanocomposites (TiO2/p...

Electrode Potential of a Dispersed Raney Nickel Electrode during Acetone Hydrogenation: Influence of the Solution and Reaction Kinetics

Pardillos-Guindet, J.,Vidal, S.,Court, J.,Fouilloux, P.

, p. 12 - 20 (1995)

The hydrogenation of acetone was investi...

-

Asai,Haruda

, (1949)

-

CATALYTIC AND STOICHIOMETRIC REDUCTION OF KETONES AND ALDEHYDES BY THE HYDRIDOTETRACARBONYL FERRATE ANION

Marko, Laszlo,Radhi, Mazin A.,Otvos, Irma

, p. 369 - 376 (1981)

Acetone is catalytically reduced to isop...

Synthesis, Characterization, Stability and Cytotoxic Evaluation of Novel Titanium(IV) Complexes of 8-Hydroxyquinoline and 2-Hydroxy-N-phenylbenzylamine Derivatives

Samuel, Blassan,Pathak, Madhvesh

, p. 683 - 689 (2020)

A new class of moisture stable heterolep...

Catalytic reduction of acetophenone with transition metal systems containing chiral bis(oxazolines)

Gómez, Montserrat,Jansat, Susanna,Muller, Guillermo,Bonnet, Michel C,Breuzard, Jérémy A.J,Lemaire, Marc

, p. 186 - 195 (2002)

The catalytic behaviour of several Ru, R...

-

Clingman,Hammen

, p. 323 (1960)

-

-

Osburn,Werkman

, p. 417 (1935)

-

Supramolecular nickel complex based on thiosemicarbazone. Synthesis, transfer hydrogenation and unexpected thermal behavior

Güveli, ?ükriye,Bal-Demirci, Tülay,ülküseven, Bahri,?zdemir, NamIk

, p. 188 - 196 (2016)

The cationic thiosemicarbazone complex o...

Engineered alkane-hydroxylating cytochrome P450BM3 exhibiting nativelike catalytic properties

Fasan, Rudi,Chen, Mike M.,Crook, Nathan C.,Arnold, Frances H.

, p. 8414 - 8418 (2007)

(Figure Presented) Divide, evolve, and c...

Hydration of Propene over Proton- and Metal Ion-Exchanged Zeolite Catalysts at Atmospheric Pressure

Mori, Hiroshi,Mizuno, Noritaka,Shirouzu, Toshihiro,Kagawa, Shuichi,Iwamoto, Masakazu

, p. 2681 - 2685 (1991)

The gas-phase hydration of propene over ...

Synthesis of uniform titanium and 1:1 strontium-titanium carboxyhydrosols by controlled hydrolysis of alkoxymetal carboxylate precursors

Riman,Landham,Bowen

, p. 821 - 826 (1989)

Uniform inorganic carboxhydrosols contai...

An adsorption calorimetry study of the adsorption of acetone on raney nickel under conditions of liquid-phase hydrogenation

Sharonov,Ulitin,Lukin

, p. S116-S121 (2006)

Adsorption calorimetry was used to study...

Propane reacts with O2 and H2 on gold supported TS-1 to form oxygenates with high selectivity

Bravo-Suarez,Bando,Akita,Fujitani,Fuhrer,Oyama

, p. 3272 - 3274 (2008)

Gold nanoparticles supported on a microp...

-

Brooks

, p. 286 (1935)

-

Hydrogenation of acetone on technetium catalysts

Rimar,Pirogova

, p. 398 - 401 (1998)

The catalytic properties of supported mo...

Effect of polyamide on selectivity of its supported Raney Ni catalyst

Jiang, Haibin,Lu, Shuliang,Zhang, Xiaohong,Tian, Baoliang,Peng, Hui,Dai, Wei,Qiao, Jinliang

, p. 776 - 780 (2016)

A newly-developed polyamide supported Ra...

EFFECT OF ISOTOPE SUBSTITUTION ON THE MAGNITUDE OF NONEQUILIBRIUM NUCLEAR POLARIZATION IN PHOTOLYSIS OF ACETONE IN METHANOL

Skakovskii, E. D.,Tychinskaya, L. Yu.,Rykov, S. V.,Yankelevich, A. Z.

, p. 2456 - 2459 (1989)

Polarization of nuclei in both the produ...

-

Remis

, (1937)

-

Effect of Fluorination of the meso-Phenyl Groups on Selective Tetraphenylporphyrinatoiron(III)-catalysed Reactions of Propane with Molecular Oxygen

Ellis, P. E. Jr.,Lyons, J. E.

, p. 1315 - 1316 (1989)

A series of tetrakis(pentafluorophenyl)i...

Ruthenium carbonyl carboxylate complexes with nitrogen-containing ligands III. Catalytic activity in hydrogenation

Frediani, Piero,Bianchi, Mario,Salvini, Antonella,Guarducci, Roberto,Carluccio, Luciano C.,Piacenti, Franco

, p. 187 - 198 (1995)

Several mononuclear and dinuclear ruthen...

Mechanistic study of propane selective oxidation with H2 and O2 on Au/TS-1

Bravo-Suarez, Juan J.,Bando, Kyoko K.,Fujitani, Tadahiro,Oyama, S. Ted

, p. 32 - 42 (2008)

The selective oxidation of propane to ac...

The role played by acid and basic centers in the activity of biomimetic catalysts of the catalase, peroxidase, and monooxidase reactions

Magerramov,Nagieva

, p. 1895 - 1900 (2010)

The acid-basic centers of heterogeneous ...

Hydrogenolysis of 1,2-propanediol for the production of biopropanols from glycerol

Amada, Yasushi,Koso, Shuichi,Nakagawa, Yoshinao,Tomishige, Keiichi

, p. 728 - 736 (2010)

Production of propanols from glycerol, w...

A Cross-Correlation Mechanism for the Formation of Spin Polarization

Tsentalovich, Yu. P.,Frantsev, A. A.,Doktorov, A. B.,Yurkovskaya, A. V.,Sagdeev, R. Z.

, p. 8900 - 8908 (1993)

Photolysis of acetone in the presence of...

Gas-phase oxidation of propylene into acetone on a V2O5/TiO2 catalyst: Effect of pressure and role of water

Chernov,Sobolev,Koltunov, K. Yu.

, p. 1439 - 1442 (2018)

The effect of pressure and role of water...

FORMULATION AND METHOD FOR SPRAY-DRYING D-TAGATOSE

-

, (2022/03/31)

A D-tagatose spray-drying feed formulati...

Time-Dependent Self-Assembly of Copper(II) Coordination Polymers and Tetranuclear Rings: Catalysts for Oxidative Functionalization of Saturated Hydrocarbons

Costa, Ines F. M.,Kirillova, Marina V.,André, Vania,Fernandes, Tiago A.,Kirillov, Alexander M.

supporting information, p. 14491 - 14503 (2021/07/19)

This study describes a time-dependent se...

A 3D MOF based on Adamantoid Tetracopper(II) and Aminophosphine Oxide Cages: Structural Features and Magnetic and Catalytic Properties

?liwa, Ewelina I.,Nesterov, Dmytro S.,Kirillova, Marina V.,K?ak, Julia,Kirillov, Alexander M.,Smoleński, Piotr

supporting information, p. 9631 - 9644 (2021/06/30)

This work describes an unexpected genera...

Hydrogen-Catalyzed Acid Transformation for the Hydration of Alkenes and Epoxy Alkanes over Co-N Frustrated Lewis Pair Surfaces

Deng, Qiang,Deng, Shuguang,Gao, Ruijie,Li, Xiang,Tsang, Shik Chi Edman,Wang, Jun,Zeng, Zheling,Zou, Ji-Jun

, p. 21294 - 21301 (2021/12/17)

Hydrogen (H2) is widely used as a reduct...

67-63-0 Process route

-

-

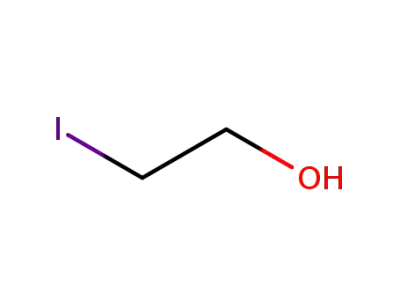

75-30-9

2-iodo-propane

-

-

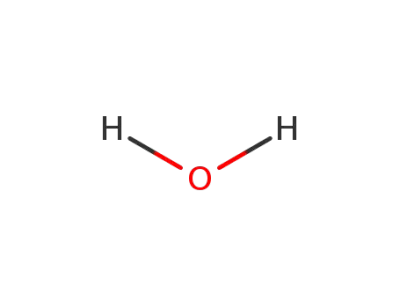

7732-18-5

water

-

-

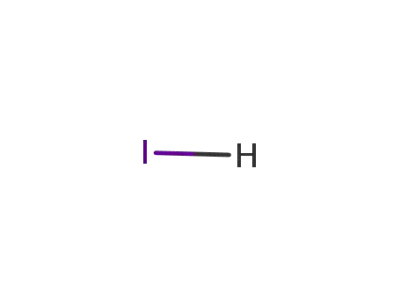

10034-85-2

hydrogen iodide

-

-

67-63-0,8013-70-5

isopropyl alcohol

| Conditions | Yield |

|---|---|

|

at 100 ℃;

im Rohr;

|

-

-

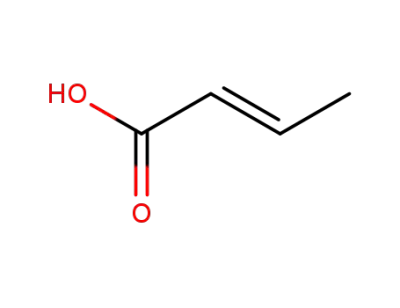

107-93-7

(E)-but-2-enoic acid

-

-

187737-37-7,13987-01-4,15220-87-8,9003-07-0,676-63-1,25085-53-4

propene

-

-

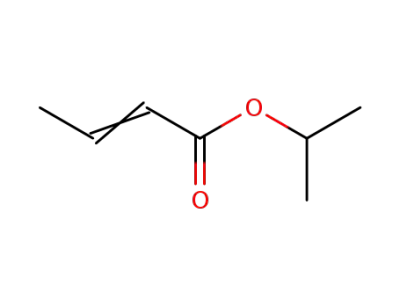

6284-46-4,17377-84-3,18060-77-0

crotonic acid isopropyl ester

-

-

67-63-0,8013-70-5

isopropyl alcohol

-

-

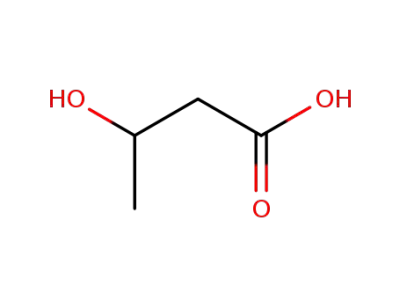

300-85-6,625-71-8,26063-00-3,29435-48-1

3-Hydroxybutyric acid

| Conditions | Yield |

|---|---|

|

With

water;

at 230 ℃;

for 1h;

Product distribution;

1M Solution of acid.;

|

4 % Chromat. 2 % Chromat. 3.3 % Chromat. |

67-63-0 Upstream products

-

75-30-9

2-iodo-propane

-

624-76-0

Iodoethanol

-

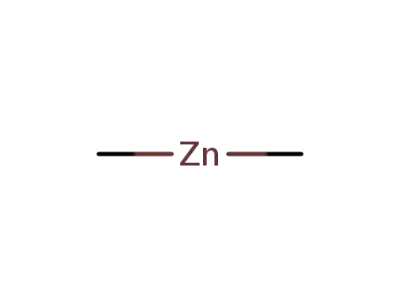

544-97-8

dimethyl zinc(II)

-

107-41-5

2-methyl-2,4-pentanediol

67-63-0 Downstream products

-

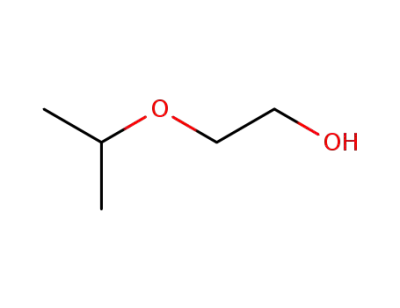

109-59-1

2-(1-methylethoxy)-ethanol

-

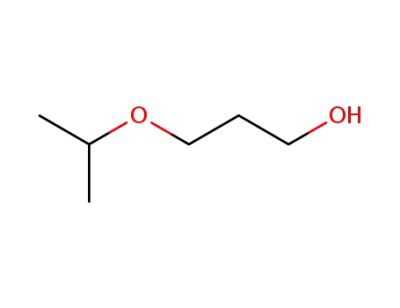

110-48-5

3-isopropoxypropan-1-ol

-

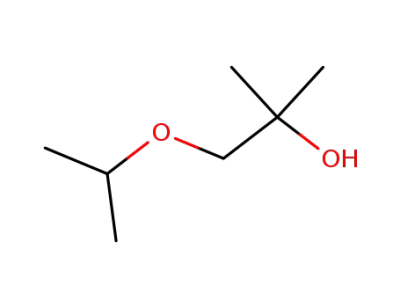

3587-75-5

1-isopropoxy-2-methyl 2-propanol

-

53146-34-2

1-isopropoxy-3-methoxy-2-propanol

Relevant Products

-

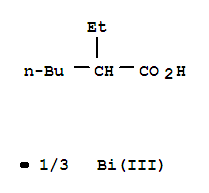

Bismuth Octoate

CAS:67874-71-9

-

2-fluorobenzonitrile

CAS:394-47-8

-

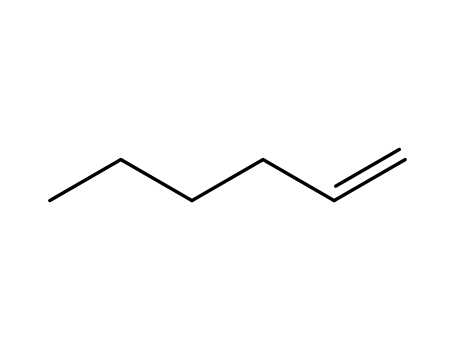

Hexene-1

CAS:592-41-6